1. Food and drug production

Food distribution, cover plate packaging seal inspection, patty inspection, caps safety package inspection, oat quality inspection.

2. Electronic products and consumer goods

PCB component testing, insoles size detection, cover detection, paper towels and so on.

3.Car

Height difference and gap detection, tire DOT code reading, clutch plate flatness detection, rubber detection.

1. Blue laser optical system

Can measure the low reflectivity of black or slope and high reflectivity of the metal, even if the color or material caused by the reflection of different object surface, can still accurately capture the shape. With blue laser, can achieve ultra-stable and high-precision measurement.

2. Ultra-high speed ultra-stable

Can be measured without any omission to achieve ultra-fast sampling of the production line or device on the high-speed flow of the product shape. In addition, high-speed sampling can also effectively reduce the measurement results.

3. High-precision online measurement

Equipped with position correction function, can cope with the measurement error is closely related to the target position offset, measurement accuracy of up to 1 micron.

4. Integral design, easy to use

The factory has been completed calibration, out of the box to measure.

5. Efficient 3D measurement software system

The DFQVisionpro vision system provides a full set of 3D and 2D detection and measurement functions to perform detection and measurement in 3D mode: height, tilt, area, and volume.

1.Argus3D Measuring instrument:

| Model | | | ARG-750G |

| Tpye | | | Desktop measuring instrument |

| Observe the measurement range | Big vision mode | (H) | 270mm |

| (V) | 160mm | ||

| Measurable height | | | 20mm(±10mm) |

| Repeat accuracy | Height measurement | | 1µm |

| Width measurement | | 5µm | |

| measurement accuracy | Height measurement | | ±1µm |

| Width measurement | | ±2µm | |

| Connection function | | | Manual(XY,Z) |

| Stage | XY travel | | 270mm(160mm)(Manual) |

| Z travel | | 90mm(electric) | |

| Rotating structure | | ±90°(θ Stage ) | |

| Tilt structure | | ±30° | |

| Operating distance | | | 75mm |

| Data processing department | | | PC |

| Fixed value | voltage | | 100 -240 VAC±10% 50/60 Hz |

| Consumption of electricity | | 150VA |

DFQ1XX Camera specifications:

| Camera model | DFQ125/DFQ107G |

| Reference distance | 250mm/75mm |

| Measuring range | Z axis(±45mm/±10mm) |

| X axis(160mm/6.5mm) | |

| Type of light source | Blue-violet laser |

| Repeat accuracy | Z axis(4μm/1μm) X axis(20μm/5μm) |

| The sampling period | 4ms |

Case 1:

Function: Depth and scratch detection

Function: Depth and scratch detection

Accuracy: +/- 0.002mm

Advantage:

2D: unable to measure

3D: high precision;

Do not rely on light, not affected by ambient light,

the effect is stable

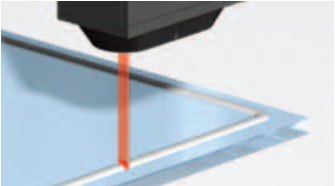

Case 2:

Function: Waterproof sealant coating test

Accuracy:+/-0.01mm

Advantage:

2D: Unable to measure uniformity

3D: high precision;

While detecting thickness and width

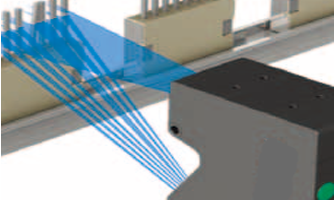

Case 3:

Function:Plug pin flatness detection

Function:Plug pin flatness detection

Accuracy: +/-0.01mm

Advantage:

2D: rely on light to light, at least two

The camera can complete the test;

3D: single camera can be a single shot to measure,

Save light and space, easy to install

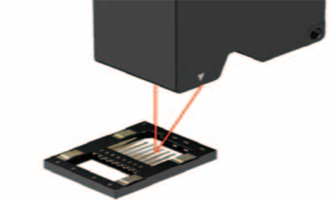

Case 4:

Function:Connector pin height measurement

Function:Connector pin height measurement

Accuracy: +/-0.005mm

Advantage:

2D: unable to measure;

3D: single shot to measure, high precision

Case 5:

Function:Thickness measurement of solder paste

Function:Thickness measurement of solder paste

Accuracy: +/-0.01mm

Advantage:

2D: unable to measure

3D: high precision;

Do not rely on light, not affected by ambient light,

the effect is stable

Case 6:

Function:Scale depth and scratches detection

Function:Scale depth and scratches detection

Accuracy: +/-0.01mm

Advantage:

2D: unable to measure

3D: high precision;

Do not rely on light, not affected by ambient light,

the effect is stable

Case 7:

Function:Chip height measurement

Accuracy: +/-0.01mm

Advantage:

2D: unable to measure

3D: high precision;

Do not rely on light, not affected by ambient light,

the effect is stable

Case 8:

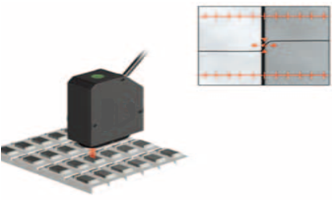

Function:Cutter depth measurement

Function:Cutter depth measurement

Accuracy: +/-0.002mm

Advantage:

2D: unable to measure

3D: high precision;

Do not rely on light, not affected by ambient light,

the effect is stable

Copyright © B&P Automation Dynamics Ltd.